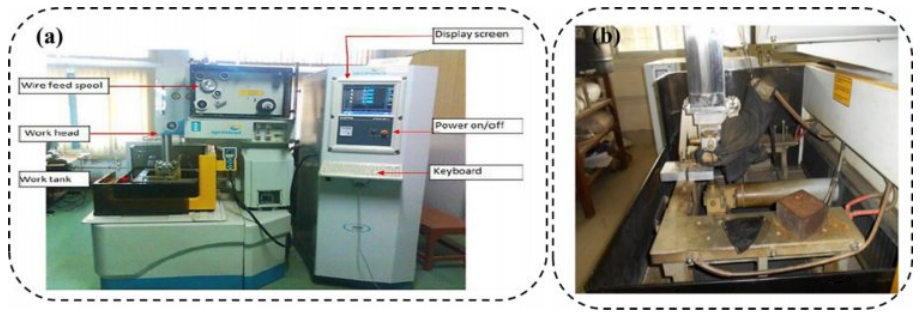

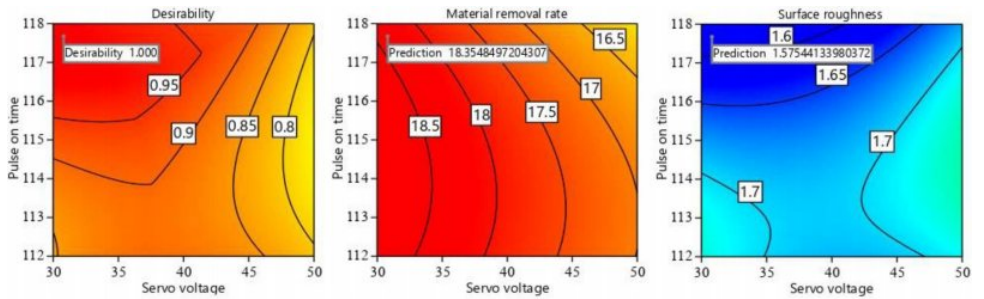

A Hybrid metal matrix composite (HMMCs) material has gained a lot of interest among industries due to its superior properties. Some of these properties are light in weight, high strength & rigidity, and high-temperature resistance. However, due to poor machinability, faster tool wear, machining of such materials exhibits greater challenges. The WEDM of aluminumbased HMMC Al6010 (10% SiC and 15% Al2O3) is investigated. The input variable viz., pulse on time (Ton), pulse of time (Toff), peak current (I) and servo voltage (V) of the WEDM process was modelled using Response Surface Methodology (RSM). The investigation was carried out through varying their effect on the material removal rate (MRR) and surface roughness (Ra). Using desirability analysis an attempt has been made to optimize the multiple responses simultaneously, the MRR and Ra were optimized for desirability and optimum result found as Ra = 1.58 µm and MRR = 18.31 mm3 /min corresponding to V = 33.32 volt, Ton = 117.45 µs, Toff = 45.041 µs and I = 219.70 A. In addition, the analysis of variance (ANOVA) is performed to determine the significance of the selected input variable. It has been found that as peak current increases, MRR increases and Ra decreases. The RSM model’s validity and appropriateness are confirmed by the test results.